1.Softening and iron ability

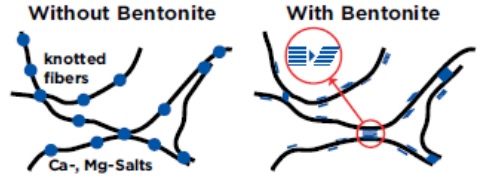

When the detergent powder used without fabric softener, after the completion of the wash and when the cloth dries, the minerals in the powder will remain on the cloth fibers in the microscopic scale and create crystals. These crystals not only decrease the flexibility of the fibers, but also will make the fibers tied up to themselves. However, when SOFONITE softener add to detergent powder, since water adsorbed in bentonite interlayer region does not vaporize during the drying process, the creation of the mineral crystals is prevented and due to the layer structure of the bentonite, the cloth fibers can easily move on each other which will lead to the cloth becoming soft and elegant. Hence ironing speed will be significantly increased and finally, while wearing the clothes, the feeling of softness and comfort is transferred. It is worth noting that this feature can be assessed with evaluating the swelling index of the bentonite.

2.Reducing water hardness

2.Reducing water hardness

Because of the negative charge on the processed bentonite sheets, SOFONITE has significant effect in absorbing the cations of the hard water. Therefore, adding SOFONITE to washing powder, while improving the performance of the detergent, prevents the crystals of water minerals to be created on the cloth fibers.

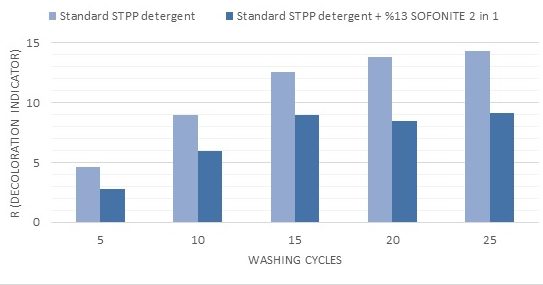

3.Color stabilization

Based on experiments done in Clariant, using this material in the detergent powder by 13%, color stabilization of the cloth will boost significantly. With repetitive washing using a detergent with this material, less color deterioration will be seen as opposed to using normal powder. In the chart below the color deterioration index of a conventional powder compared to the one with 13% of this product is illustrated.

4.Preventing the cloth fiber from wearing out

Since mined bentonite usually includes a significant amount of free silica as an impurity, using mineral bentonite without the purification process will cause a significant amount of free silica crystal to enter the detergent powder. It is obvious that the hardness and incisiveness of the silica will cut the cloth fiber after some washing cycles. However, the first step of producing SOFONITE 2 in 1 is three level bentonite purification for separating impurities in the scale of gravel, tiny sand and micronized particles which is done using the best machinery in Khak Rangbar factory. On average, 2 kilograms of raw bentonite from the mine will eventually produce 1 kilogram of fully pure bentonite which is used in the production line.

5.Completely white color

The white color has always been a symbol of cleanness and therefore attracted a lot of attention from the detergent producers. Various impurities in the raw bentonite, however, causes undesirable colors like grey, brown, green etc. Doing the purification process for producing SOFONITE 2 in 1, the color of the material is completely white and preserves the powder display.

6.Environment friendly

Since SOFONITE 2 in 1 is the result of processing a type of natural clay (bentonite), it is fully environment friendly and using it will not cause any bad effect on the quality of the clothes, human health and pollution of underground water. This matter shows the advantage of bentonite softener against other organic softeners.